Briefly noted

READING TIME 6 MIN

New products, new services and trends Briefly notedicon blue background information original

Listen to article

Excellent safety technology

Siemens Austria is the first company certified with new ÖVE/ÖNORM EN 16763

The OVE (Austrian Electrical Engineering Association) has certified Siemens AG Austria as an installer of security systems (alarm, video and access) in accordance with ÖVE/ÖNORM EN 16763. Siemens AG Austria is thus the first company to receive the certificate. The certification process is aimed at installers of security systems — this includes burglary and robbery alarm systems (OVE guideline R 2), video surveillance systems (OVE guideline R 9) and access control systems (OVE guideline R 10). In March 2025, the audit was successfully completed for all Siemens branches in Austria. In accordance with the established regulations, a mandatory on-site inspection of an alarm system and an additional video or access system is carried out every two years. This ensures that the systems are always up to date and meet the requirements. In addition, recertification is required after four years.

Flexible festivals

Secure access with a mobile solution from Siemens

The Salzburg Festival and Siemens have worked together to prove what maximum flexibility can look like in the middle of the festival summer. The Salzburg Festival Hall was affected by disruptive actions by activists this year. The organizers responded with stricter controls at entrances, more security personnel and more police presence — and with an add-on solution from Siemens to the existing SiPort access system. SiPort allows you to manage personal and building data in real time and offers an intuitive user interface for easy operation. Even before the events of this year’s summer, all areas and entrance doors were secured technically or personally, but now an additional

security gate has been added to the SiPort access system in the form of a mobile solution with mobile devices and verification software. The special thing: Only a week has passed from problem presentation to commissioning of the first test system thanks to the rapid response of the Festival and Siemens team — and the solution is already in operation right in the middle of the peak phase of the cultural summer!

More performance and flexibility

Intelligent Valve with new firmware version

The Intelligent Valve with the new firmware version 1.22 offers a number of improvements: performance, flexibility and communication options. The permitted temperature range has now been extended to —10°C when the valve is operated with ethylene glycol-water mixtures. At the same time, the possible concentration range of ethylene glycol is up to 50% (up to now a maximum of 30%). The maximum volume flow rate is now reduced to a minimum of 5% (previously 30%). The extended differential pressure control can now work with either two separate pressure sensors or a single differential pressure sensor. There are two new limits: a weighted return temperature limit and an adjusted maximum output limit. In addition, a Key Performance Indicator (KPI) is now available as a BACnet object.

50 years of safety

VSÖ celebrates 50th anniversary — Siemens was there as a founding member

In May of this year, the Austrian Association of Security Companies (VSÖ) celebrated its 50th anniversary — with Siemens as one of the founding members. Since the association was founded, the security landscape has developed significantly: While police emergency call systems from Siemens AG Austria were installed in all towns in the province of Salzburg with more than 10,000 inhabitants in the 1970s, Siemens’ current security portfolio includes a wide range of modern technologies — including access control systems, video surveillance, burglar detection technology and comprehensive cybersecurity solutions.

With “Building X Security Manager,” Siemens is setting new standards in digital building security. The cloud-based platform enables holistic, open and interoperable management of security-relevant systems and processes. It helps companies make their security infrastructure efficient, transparent and future-proof. As an active member of the VSÖ, Siemens is not only involved technologically but also strategically: Our company continuously contributes its expertise to the development and revision of industry-specific guidelines and standards — and thus makes a significant contribution to the quality assurance and innovative strength of the Austrian security industry.

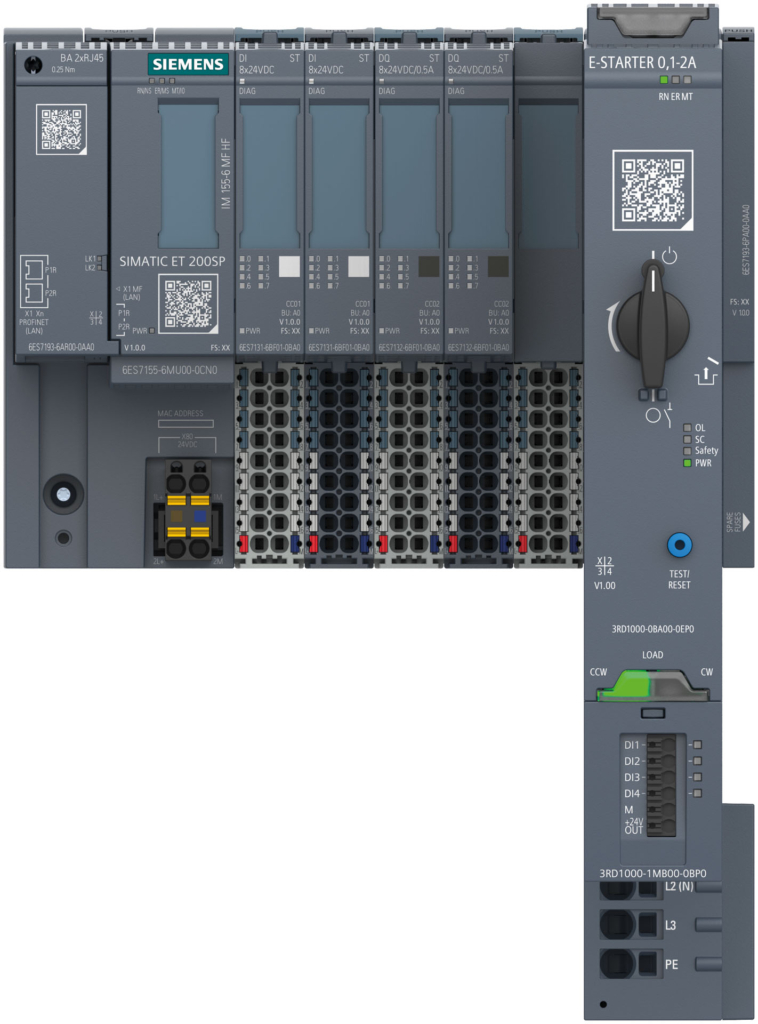

Sentron switches faster

The SENTRON ECPD (Electronic Circuit Protection Device) is one of the first protective switching devices worldwide that switch electronically. It impresses with ultra-fast switching, flexible parameterization and an enormous range of functions.

SENTRON ECPD switches ultra-fast, can be flexibly parameterized and saves resources. Its multi-functionality makes it possible to reduce the width of modules in the control cabinet from 16 to just 2 units. The idea: Series connection of cutting-edge semiconductor technology with electromechanical components in a protective switching device. The result: a paradigm shift in circuit technology. The advantages: outstanding short-circuit protection, excellent pulse resistance and selectivity.

Electrical installations have always required the use of suitable overcurrent devices to protect equipment and people from damage. In the beginning, fuses were used for this purpose, but later they were increasingly replaced by reusable, electromechanically separating switches. This working principle had changed little for many decades.

State-of-the-art semiconductor technology

However, Siemens is now breaking new ground with the SENTRON ECPD 5TY1 COM electronic circuit breaker: For the first time, the SENTRON ECPD uses cutting-edge semiconductor technology with electromechanical components to connect the main current path in series. Its intelligent protection algorithm is therefore significantly faster and more precise than electromechanical solutions. Numerous additional functions can be activated and adapted as required.

There are completely new options for planning, installing and operating the energy distribution system. Whether designing cables according to nominal current peaks instead of inrush current peaks, reliable short-circuit detection for long lines, support for operational energy management in accordance with ISO 50001, targeted consumption and cost reductions in operation, remote diagnosis and remote access or sustainability gains: The SENTRON ECPD sets new standards for innovation and sustainability in electrical energy distribution and is therefore another exemplary product that bears the Siemens EcoTech label.

Highlights at a Glance:

Ultra-fast – Short circuit without short-circuit current

• Minimal short-circuit energy thanks to switching up to 1,000 times faster

• >99% reduction in let-through energy allows for material-saving cable design

Multifunctional – One device, unlimited possibilities

• Numerous functions integrated into the protection switching device and can be activated as needed

• More efficient planning and installation, reduced space and copper requirements

Configurable – Individuality down to the finest detail

• Perfect, demand-based customization for every application

• Higher availability through full selectivity and improved fault handling

Sustainable – Resource conservation as a holistic concept

• Massive material savings and reduced recycling load

• Significantly lower power loss, condition-based maintenance, rapid troubleshooting

You can find more information here.

It has the touch

The TC4 all-in-one room control unit for optimum comfort

The Touch Control TC family is growing — the new Touch Control TC4! The room unit impresses with an elegant design, two color options and all the functions already familiar from the Siemens Touch Control room control unit family. Integrated temperature sensors and various KNX room control options enable optimal conditions. Features include password protection, proximity sensors, alarm lights, 15 languages, and firmware updates. The user interface can be personalized (backgrounds, icons, languages), with up to 15 function pages configurable via ETS for date, time and schedules. As a versatile KNX room controller, it supports lighting, sun protection and manages HVAC systems (temperature, ventilation, heating/cooling) using an integrated NPI controller. KNX Data Secure provides increased security.

In the light of art

Lighting control with Siemens DALI technology

Siemens DALI (Digital Addressable Lighting Interface) stands for intelligent and efficient lighting control in modern buildings and is an international standard that enables digital communication between lighting devices such as lights, sensors and control elements. Siemens seamlessly integrates DALI technology into its building automation systems, particularly in solutions such as Desigo or KNX. This allows precise, individual and flexible control of each individual lamp or group of luminaires.

The benefits of Siemens DALI solutions are manifold: They enable significant energy savings through daylight-dependent regulation and presence control. They also offer maximum comfort through personalized lighting scenes and easy adjustment to changing room uses. Digital addressability significantly simplifies installation and maintenance. Siemens DALI components also ensure high reliability and interoperability.

With their powerful and intelligent functions, the KNX/DALI gateways are redefining lighting control. They offer what you would expect from a dynamic, human-centered lighting system: easy implementation, seamless integration, increased energy efficiency, and simple and time-saving start-up. These gateways are designed to adapt lighting to today’s needs and ensure that functionality and ease of use go hand in hand.

Whether in offices, schools, hospitals or industrial plants — Siemens DALI makes a significant contribution to sustainable, convenient and future-proof lighting solutions that increase efficiency and well-being.

You can find more information here.